WSNet

Unsere WSNet-Lösung bietet mit ihrer Funktechnik entscheidende Vorteile in den Bereichen Reichweite, Störfestigkeit und Stromverbrauch. WSNet basiert physikalisch auf der LoRa™-Technik, stellt aber eine von WSN für den jeweiligen Anwendungsfall maßgeschneiderte Lösung dar. Im WSNet wird nur so viel Energie für das Senden und Empfangen der Daten aufgewendet, wie tatsächlich erforderlich ist.

Die Vorteile der IIoT-Lösung auf einen Blick:

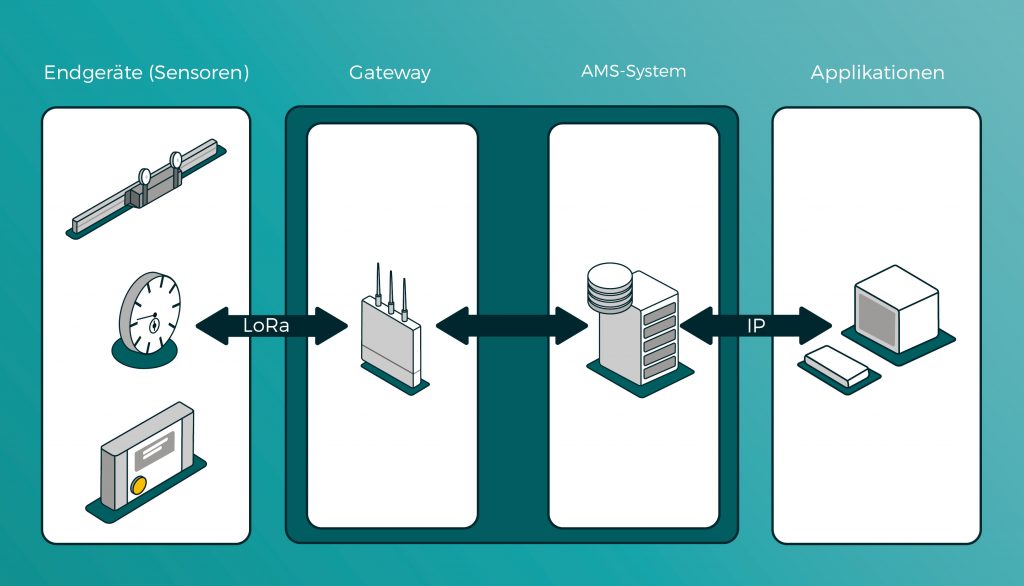

Komponenten der WSNet-Lösung

Komponente 1 - Funknetz: WSNet-Basis LoRa™

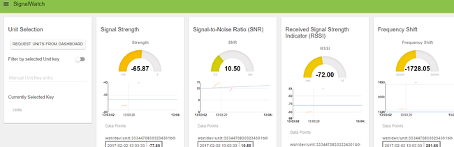

Durch die robuste Wireless-Technologie LoRa™ wird im Industrieumfeld eine gute Abdeckung und Durchdringung auch großer Fertigungshallen erreicht. Die Funktechnologie ist eine Entwicklung der Firma Semtech Corporation. Im Unterschied zu WLAN werden keine Vielzahl an Routern benötigt. Ein einzelnes LoRa™-Gateway ist in der Lage, Hunderte von Sensoren auf Tausenden Quadratmetern zuverlässig und sicher zu managen.

Aufgrund der von LoRa™ verwendeten „spread spectrum technology“ (Frequenzspreizung) ist es möglich, verschiedene virtuelle Kanäle gleichzeitig zu nutzen, ohne dass die Übertragungen sich gegenseitig stören. Sowohl die Datenraten, die Frequenzen als auch die Sendeleistungen der Endgeräte können individuell eingestellt werden. Durch die Störfestigkeit und hervorragende Durchdringung eignet sich diese Technik hervorragend für den Einsatz innerhalb von Gebäuden und funktechnisch kritischen Umgebungen (z.B. in Stahlbeton-Bauten).

Die wichtigsten technischen Daten und Vorteile in Kürze:

- Nutzung der innovativen LoRa™-Funktechnik als physikalische Grundlage zur Datenübertragung zwischen Endgeräten und Basisstationen (Gateways – Vgl. Aktoren weiter unten im Artikel)

- große Reichweite (sowohl innerhalb als auch außerhalb von Gebäuden)

- einfache Installation und Inbetriebnahme des Netzwerkes

- geringe Installationskosten als Einmalkosten, selbst bei Netzwerken mit großer räumlicher Abdeckung: Mit nur wenigen Gateways können mehrere Tausend Endgeräte vernetzt werden.

- es sind keine weiteren (nicht-administrierbaren) Repeater nötig

- Nutzung freier (ISM-)Bänder: Keine Lizenzgebühren, keine laufenden Nutzungskosten

- sternförmige Topologie, wobei Gateways typischerweise als transparente Brücke zwischen Endgeräten und dem Message Management Center (MMC) fungieren

- bidirektionale Kommunikation zwischen Endgeräten und Gateways, bzw. Applikationen

- zentrale und wahlweise vollautomatische Einbindung und Konfiguration der Endgeräte

- privates Netzwerk – Daten müssen nicht über ein öffentliches Netz übertragen werden

- hohe Datensicherheit gegen Hackerattacken durch zweifache AES128 Verschlüsselung (Hard- und Software) zwischen Endgeräten und Gateway

- SSL-Verbindungen im IP-Netz

- kein Verbrauch privater IP-Adressen durch die Endgeräte. Lediglich das Gateway belegt eine IP-Adresse, Endgeräte benötigen keine eigene IP-Adressen sind jedoch eindeutig adressier- und lokalisierbar.

- Roaming ohne Datenverluste bei mobilen Endgeräten

Komponente 2 - Endgeräte: Sensoren und Aktoren

Die Sensorik der Lösung besteht u.a. aus mechanischen oder optischen Schaltern für Regale und Rollenbahnen, Belegtmelder für Paletten und Gitterboxen, Füllstandanzeiger für Schraubenbunker usw. Die batteriebetriebenen Sensoren sind mit einem Low-Power-LoRa-Funkmodul ausgestattet und zeichnen sich durch Robustheit und sehr lange Batterie-Laufzeiten aus.

Passive Sensor Nodes (PSN)

- senden Nachrichten (ereignisgesteuert) an das Message Management Center (Software – Vgl. Späterer Textverlauf Komponente 3)

- stehen nur zu vorkonfigurierten Zeiten für den Empfang von Kommandos zur Verfügung

- dieser Modus ist der batterieschonendste Betriebsmodus mit bis zu 10 Jahren Batterielaufzeit

- Produktbeispiel: Rollenbahnsensor

Active Sensor Nodes (ASN)

- nutzen die „Wake on Radio“ (WoR) Funktionalität. Basierend auf der Konfiguration des Endgerätes ist dieses für ein voreingestelltes Intervall dauerhaft empfangsbereit.

- Diese Nodes akzeptieren Kommandos vom Message Management Center, beispielsweise um eine LED zu schalten.

- Dieser Modus ist aufgrund der häufigen Empfangsbereitschaft weniger energiesparend als der Betrieb als Passive Sensor Node. In typischen Industrieanwendungen erreichen diese Endpunkte ca. zwei Jahre Einsatzzeit ohne Batteriewechsel.

- Produktbeispiel: Call Button

Gateways

- Die Gateways fungieren als Medienwandler und verfügen über mindestens zwei LoRa-Funkeinheiten (Transceiver) und eine IP-Anbindung über LAN/WLAN/Mobilfunk (je nach Ausstattung). Die LoRa-Funkeinheiten nehmen folgende Aufgaben wahr:

- Outbound Message Channel (OMC) – dient dem Versenden von Kommandos / Informationen an Endgeräte

- Inbound Message Channel (IMC) – empfängt Nachrichten von den Endgeräten

- Durch Einsatz eines sogenannten „Concentrator“ Moduls können bis zu 48 Nachrichten gleichzeitig verarbeitet werden.

Alle Nachrichten / Kommandos folgen der WSN Avro Spezifikation zur effizientesten Datenübertragung.

Komponente 3 – Software und Message Management Center

Das Message Management Center (MMC) verwaltet WSNet-Endgeräte und kommuniziert mit diesen über Gateways. Die Kommunikation mit Applikationen erfolgt über Standard IP-Verbindungen. Es kann sowohl auf dem Gateway als auch eigenständig auf einem PC betrieben werden.

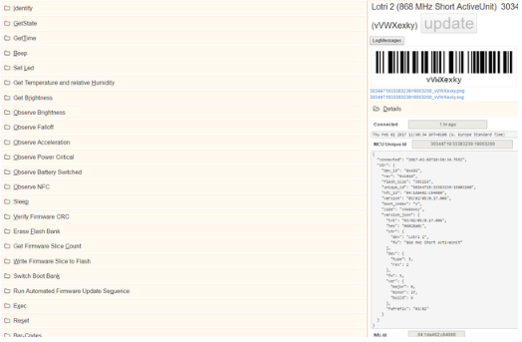

Das MMC verfügt über ein sogenanntes Dashboard, also eine Bedienoberfläche zur zentralen Überwachung und Steuerung aller am Gateway angemeldeten Endgeräte. Das Dashboard erlaubt die direkte Kommunikation mit den Endgeräten. Es protokolliert darüber hinaus alle eingehenden Daten und Ereignisse.

Unser MMC unterstützt über das Dashboard ein Update der Firmware für die Endgeräte. Diese können entweder einzeln oder per Multicast eine neue Firmware „over-the-air“ erhalten. Aus Sicherheitsaspekten kann nur signierte Firmware auf Endgeräte übertragen werden.

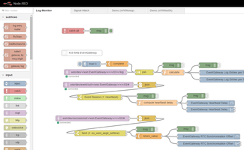

Einbindung von Node-RED

Node-RED als grafisches Tool zur Erstellung von Nachrichtenverläufen

Node-RED Message Flow (Beispieldarstellung)

Ein weiteres Kernstück des MMC ist der Einsatz von Node-RED. Einem grafischen Tool zur Erstellung von Nachrichtenverläufen. Es erlaubt Endgeräten, sich mit Schnittstellen von Applikationen zu verbinden, E-Mails oder Tweets ereignisbasierend zu versenden oder einfach nur Endgeräte komfortabel zu überwachen. Node-RED unterstützt MQTT, ein Echtzeit-M2M-Message-Protokoll.

Node-RED Message UI (Beispieldarstellung)

Alles aus einer Hand

Die Wireless-IoT-Anwendungen werden an die jeweiligen betrieblichen Systeme angebunden und in die Unternehmensprozesse integriert. Dazu erfolgt vor Ort eine Bestandsaufnahme, um das Lösungskonzept, die Komponenten und die Software an die örtlichen Anforderungen anzupassen. Die Turn-Key-Solution umfasst außerdem die Installation, Inbetriebnahme, Schulung und den Support.