Products

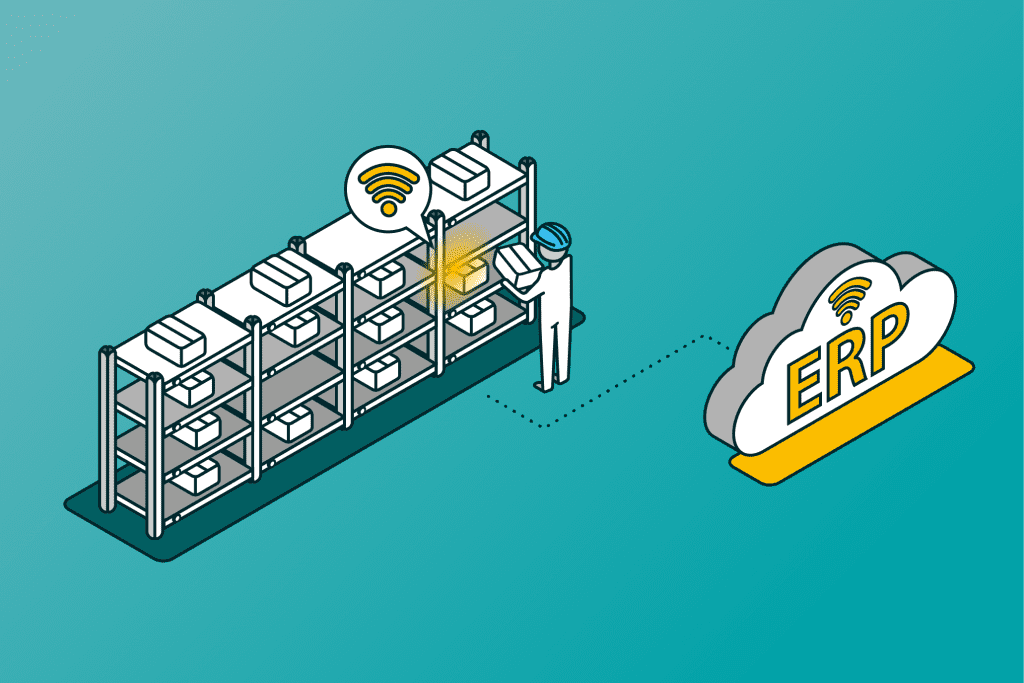

WSNet is based on wireless sensors and actuators that record the occupancy status of small and large load carriers, display the material requirements and transmit them to materials management. All products can be adapted to the respective customer requirements as required.

Occupancy sensor for material flow

Occupancy sensors are a common means of increasing efficiency and process reliability in material supply Using AGVs, cable cars or conveyor belts, not only raw but also intermediate products are fed to the next required production steps. The occupancy detectors check the status of material locations, automatically trigger actions such as triggering transport orders and thus synchronize the material flow. A distinction is made between two types of detectors, which depend on the type of sensory detection: The material can be reported either when it is parked (stationary) or when it passes (flowing) at a defined location. Both sensor variants are permanently installed in the electrical and mechanical system for use in material flow control and networked with the existing operating software as required.

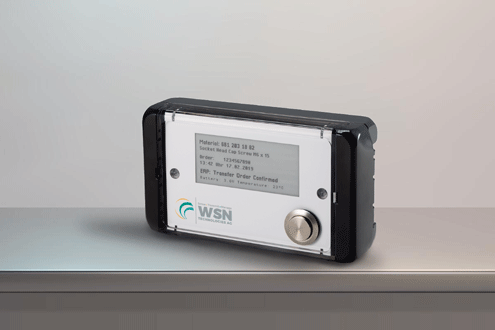

Callbutton

At the push of a button, the radio-assisted call button enables a quick and error-free request, e.g. of large load carriers (GLT). This is alsoavailable with an integrated display, which expands the range of functions of the call button. In this way, information about the status can also be called up, such as: order status, action warnings and instructions or illustrations of construction drawings.

More information and technical details about the product can be found in our data sheet:

Gateway

The WSNetGateway is amedia converter andthus an interface between sensor and actuator end devices. The design as a concentratorgateway with up to eight receivers that can be used simultaneously, enables the simultaneous communication and management of more than hundred end devices. It is easy and flexible to configure andadministrate.The robust and dustproof housing is particularly suitable (protection class IP6X) foruse in harsh industrial environments.

More information and technical details about the product can be found in our data sheet:

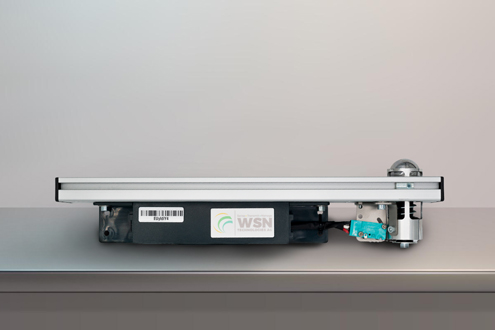

Palette switch

Pallet storage areas can be actively managed with the WSN pallet switch. The robust pallet sensor detects and records the occupancy of storage areas. This enables active management of places and replenishment. The sensor is battery-operated and integrates seamlessly into the material replenishment system. For further information and technical details about the product, please contact us at any time.

Pick-by-Light

With the help of electronic compartment displays (signal lights) and paperless picking, pick-by-light systems support employees in picking goods. A successful extraction is confirmed at the push of a button and the order pickers are navigated to the next extraction requirement by a new compartment display light up.

Behind the mechanism is a software that also plans intelligent route guidance, thereby shortening walking distances. The modular, adaptable and cable-free system also offers the following advantages:

- Quick and easy onboarding of new employees.

- 100% paperless. Upon request, in combination with analogue lists.

- Increase in extraction providing stock reliability.

- Reducing the error rate and promoting a positive working environment.

Put-to-Light

With the help of electronic signal lights on site, pick-to-light systems support employees when storing goods. The train is loaded according to the requirement list. Behind the subsequent procedure is a software that intelligently plans the list of requirements according to urgency as well as providing the ideal route With the signal lamps lighting up one after the other, route train drivers can use this modular and wireless system to easily store material and goods at the right destination. At the push of a button, the successful filling is then confirmed by the qualified employee.

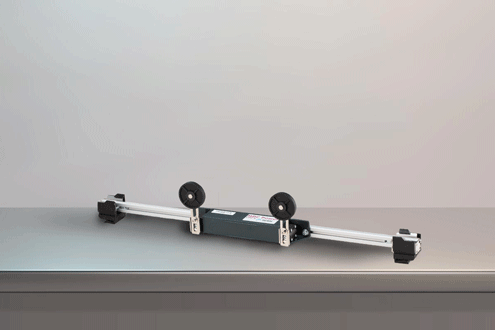

Roller conveyor sensors

Rollerconveyor sensors developed by WSN, reliably record the occupancy status of roller conveyor spaces. They are extremely flexible, thanks to the integrated WSNet radio module. The vacancy of a replenishment container location is reportedwirelesslyvia gateway to the product management systemand it then triggers a material request.. The mounting concept of the SLR sensors with support rails is compatible with all common flow rack systems, e.g. from SSI Schäfer, Bito, ITEM, Creform etc. The housing is robust and dustproof, making it ideal for industrial environments.

More information and technical details about the product can be found in our data sheet:

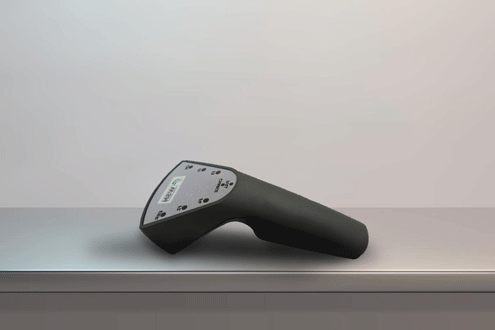

Scanner

The SLS 200 is a lightweight and robust pistol grip scanner. It offers wireless data transmission over distances of several hundred meters using the integrated LPWAN radio modem. It reliably reads 2D codes from a distance of up to 30 cm.. The desired reading area is simply marked with a target point and scanned at the push of a button. The pistol grip scanner was specially developed for use in harsh industrial environments. The battery life lasts longer than a typical production shift, even with scan-intensive applications.

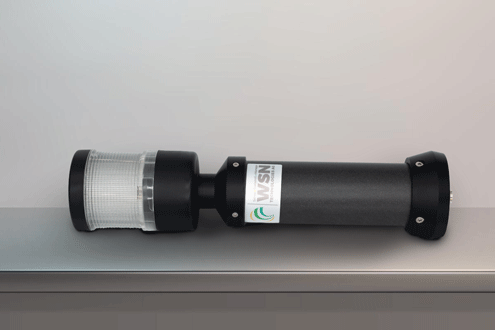

Signal lamps

Display occupancy status, hazards as well as the fastest route through the factory simply by means of a light signal.. The WSNet signal lamps are multifunctional lights that can be operated with mains voltage or batteries. . The signal lamps can be integrated into the infrastructure via simple interfaces and are controlled by radio. Each lamp type has its own signal rhythm. Depending on the type of use, these can be all-round, flash quickly, flash periodically, emit pulsating signalsor emit a permanent light signal.

WSN Technologies from Braunschweig

Please contact us if you are interested in a business or scientific cooperation.

We are looking forward to your inquiry!

WSN Technologies AG

Frankfurter Str. 3a

38122 Braunschweig, Germany

+49 (0) 531 24556-290